I recently received a testimonial from a service technician in Wichita, Kansas. He told me his customer brought in a 2006 Chevy with 3.6L engine, and the oil light was on. It had been 15,000 miles since the last oil change! Her engine was completely sludged, and it actually sounded like a diesel. The technician figured it needed a new engine; but then remembered his BG Rep talking about a BG EPR® Engine Performance Restoration®, PN 109. The tech admitted he didn’t think it would work; but what the heck. He cleaned the valve cover and pan and did two oil changes using BG EPR®. Much to his surprise, halfway through the second service, the engine quieted and smoothed out. He saved that lady several thousand dollars, and she’s still driving the car today!

The results are in: BG EPR® is outstanding!

New technology needs BG EPR®

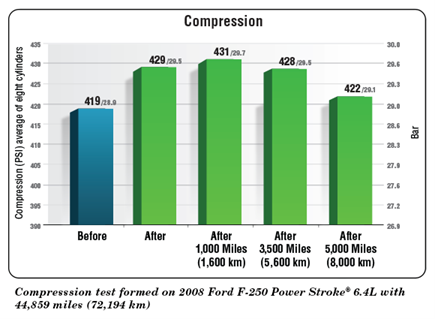

As technology evolves around engine design, we are finding that the use of BG EPR® is becoming critical to maintain the integrity of the engine. Sophisticated engine management systems are put in place to provide better engine flexibility with the intentions of increasing fuel economy, power and lowering emissions. These engine management systems involve complex mechanical, electrical and hydraulic operating systems inside the engine.

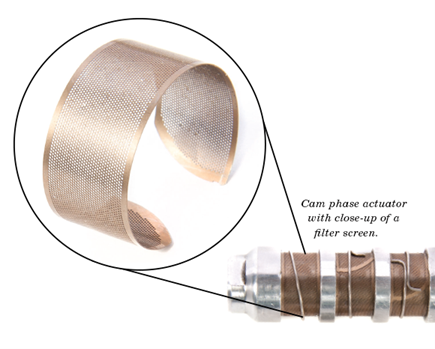

The most common of these systems is Variable Valve Timing (VVT). These systems are protected by small screens (filters) that keep contamination from interfering with operations. If these screens get contaminated with sludge, the system can’t operate properly and the result is a poor running engine. (Reference Ford TSB number 11-2-10) There are many other systems that are oil driven including Variable Geometry Turbo (VGT), Hydraulic Electric Unit Injector (HEUI) diesel fuel injectors, piston cooling jets for GDI engines, engine oil coolers and the list goes on.

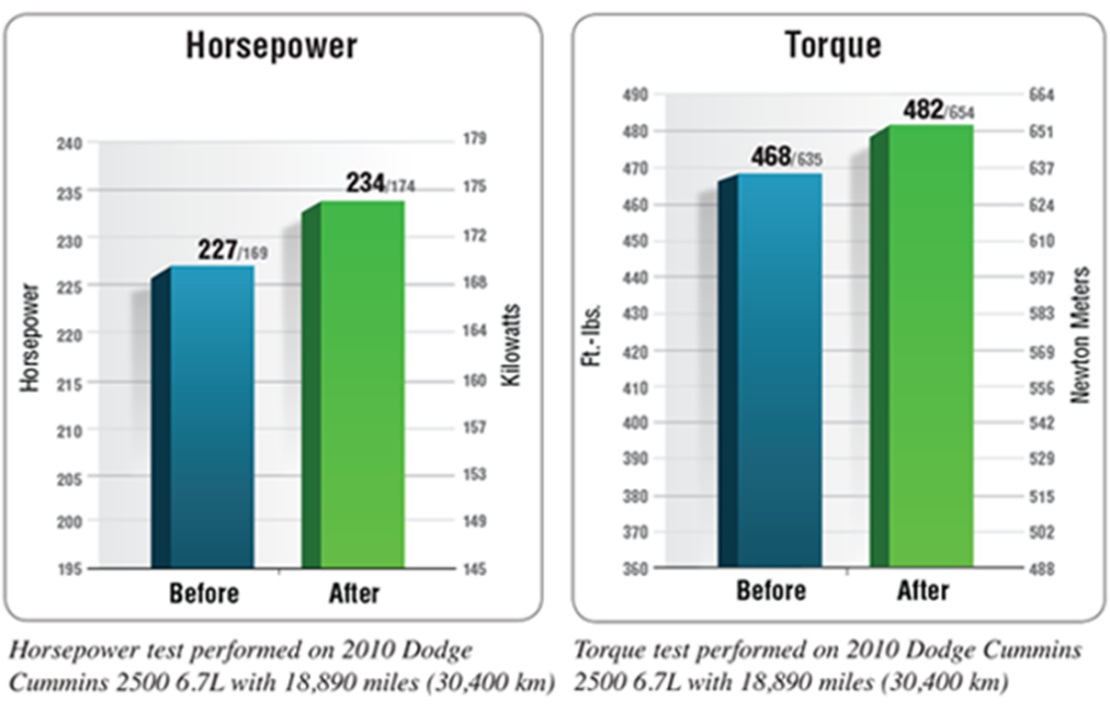

Routine maintenance with BG EPR® will greatly increase the efficiency of these engine management systems, while restoring fuel economy, performance and lowering emissions.

Diesels need BG EPR®