Since the invention of the gasoline engine, carbon deposits, oil oxidation, and oil evaporation have been inevitable and wreaking havoc in an internal combustion engine.

One case study at a time, the BG Proving Ground is demonstrating the inherent issues in these engines and proving that aftermarket products like BG products can prevent those issues and help the engine perform better, longer.

This time, we pushed the burden of proof to the next level. We pulled a 2015 5.3L GDI VVT AFM General Motors engine from the salvage yard.

Engine Prep for Testing

Salvage yard engines are drained of all fluids, so we had some work ahead of us to get this engine running. We added an OEM engine oil filter and OEM engine oil and then inspected it for any defects that could affect performance results. All factory accessories remained intact. We disabled the traction control/security features and fabricated an exhaust system including: OEM catalytic converters, OEM oxygen sensors, and emission gas probes.

Next, we fit it to the engine dynamometer for baseline testing.

- Engine power and sensor data was collected via HP tuners and Super Flow Dyno Software.

- Emissions were recorded pre- and post-catalytic converter (at idle and off idle).

- Fuel consumption was measured using AVL Plutron. (AVL Plutron is the standard tool used in fuel consumption testing by most of the OEMs and EPA/CARB and other emission regulatory bodies around the world.)

- Warm compression was collected using a Pico oscilloscope and analog pressure gauge.

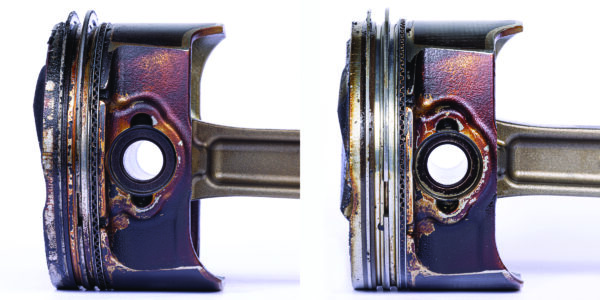

- The engine was disassembled to measure and photograph internal parts: intake valves, combustion chamber, piston tops, etc.

Enter BG

Knowing what we know about GDI engines, we selected the BG Engine Performance Service and the BG Platinum® Fuel System Service to restore this junkyard engine.

- Added EPR® Engine Performance Restoration® to the engine oil and ran at an elevated 1200 RPM for 20 minutes.

- Drained oil and replaced the oil filter. The crankcase was refilled with factory specification oil and BG Advanced Formula MOA®.

- Performed the BG Platinum® Fuel System Service using 44 ounces of BG Platinum® Air Intake, Valve & Combustion Chamber Cleaner. The service was broken into two parts of 22-ounce doses with a 15-minute idle in between doses.

- BG Platinum® 44K® was added to the fuel cell. The vehicle ran through a complete tank of the 20-gallon fuel cell to administer fuel treatment and disperse any cleaner left from the BG Platinum® Fuel System Service.

- Refilled the 20-gallon fuel cell with untreated fuel.

Results: The Moment of Truth

To ensure maximum accuracy, we performed tests in exactly the same manner as the baseline.

Compression

Cranking compression, measured at 350 RPM, showed an evening out across all cylinders.

What does that mean?

This is a sign that the piston ring function has improved. Restored compression is noticeable when you drive; you can feel a smoother idle and running engine in addition to noticing it in the fuel economy. Poor compression shows up as abnormal idling, power loss, higher fuel consumption, and polluting emissions.

Intake Valve Weights

We measured the change in weight on the valves. The difference in weight would indicate carbon deposit removal. Weight reduction, on average, was 0.4963 grams. (This is a decent amount when dealing with carbon on valves.)

What does that mean?

Intake valve deposits are particularly hard to clean in GDI engines. This amount of carbon could affect the gas mileage, impact the fuel/air ratio, and cause stuck valves or damage. More on fuel consumption later.

Crankcase Pressure

A pressure transducer and oscilloscope helped measure crankcase pressure. Over 1 million samples were taken and averaged to get accurate results. Crankcase pressure decreased by 26%.

What does that mean?

Piston ring function improved, which meant a marked decrease in blow-by. Blow-by is the cause of many different malfunctions in an engine from increased oil evaporation to decreased injector flow.

Emissions

As you can see in the chart, the emissions test showed a significant drop in emissions across the board. The lambda is close to perfect. A lambda reading on a gas tester is an indication of the air to fuel ratio—too high of a lambda reading relates to too much oxygen, too low of a reading relates to too much fuel.

What does that mean?

The emissions tests can be an indicator of the overall health of the vehicle. When emissions are high, it can point to issues with valves, injectors, air/fuel ratio, and more.

Fuel Mass Flow Rate

The fuel mass flow rate was measured during all three fuel consumption tests with the resolution of over a million samples per run. Each fuel consumption run was timed at exactly 60 minutes of runtime at the same engine load, temperature, and ambient conditions.

A decrease of five percent mass flow rate was observed during the testing. This is evidence of the increase in efficiency with the engine being able to use less fuel and maintain the same engine load. The fuel injectors averaged 2–3 mL more fuel in 6,000 rpm dynamic flow tests, and fuel consumption was reduced by eight percent!

What does that mean?

Better gas mileage is the easiest explanation here, and that’s something we could all use right now.

Key Takeaway: BG Restored the Junkyard Engine

The results of this case study show a clear benefit to implementing an aftermarket fuel and oil maintenance program.

Reducing the level of carbon inside the engine will:

- Decrease the incidence of repair caused by carbon buildup.

- Improve overall engine efficiency through maintaining horsepower and torque.

- Restore fuel economy.

- Reduce emissions by maintaining proper fuel injector function.