Research Summary: Ford Mustang 2.3L EcoBoost Engines

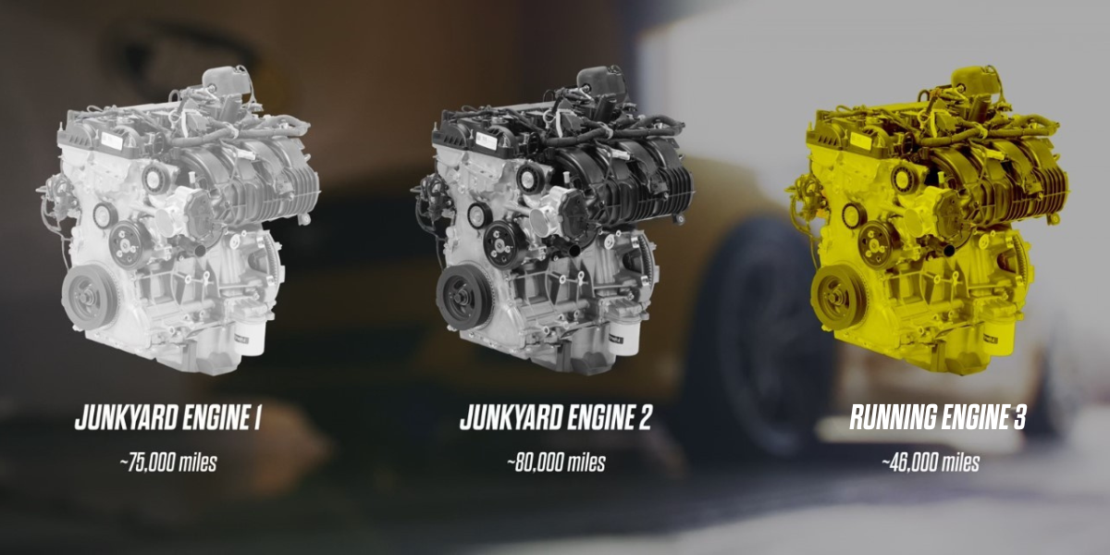

The BG Proving Ground team studied the engine performance and efficiency of two downsized turbocharged (2.3L EcoBoost) engines from 2015 Ford Mustangs with 75K and 80K miles, respectively. Both engines were salvaged, and both had received only factory maintenance. The team ran baseline dynamometer testing to determine the health, performance, and efficiency of these engines; they then performed a BG Engine Performance Service and a BG Platinum® Fuel System Service on the two engines and tested them both again.

In order to confirm the results with a third engine retrieved from a running, driving car, BG Products purchased the same kind of vehicle with the same kind of engine, this one with 46K miles. The Proving Ground team got to work running the same tests on this third engine.

The BG Proving Ground team put three engines (and two BG Services) to the test.

Two BG Services

The BG Engine Performance Service is BG’s top-of-the-line engine service—a three-part deep cleaning of the vital components in the engine. It dissolves deposits, prevents sludge buildup, and restores fuel economy.

The BG Platinum® Fuel System Service helps protect today’s engines from the damaging effects of high heat and pressure. These conditions cause the rapid accumulation of carbon deposits on intake valves and fuel injectors and in combustion chambers. This premium, restorative service results in noticeably smoother performance and enhanced drivability.

Intake Valves

Piston Tops

Fuel Injectors

Fuel Injector Port Holes

Test Results

Cranking Compression

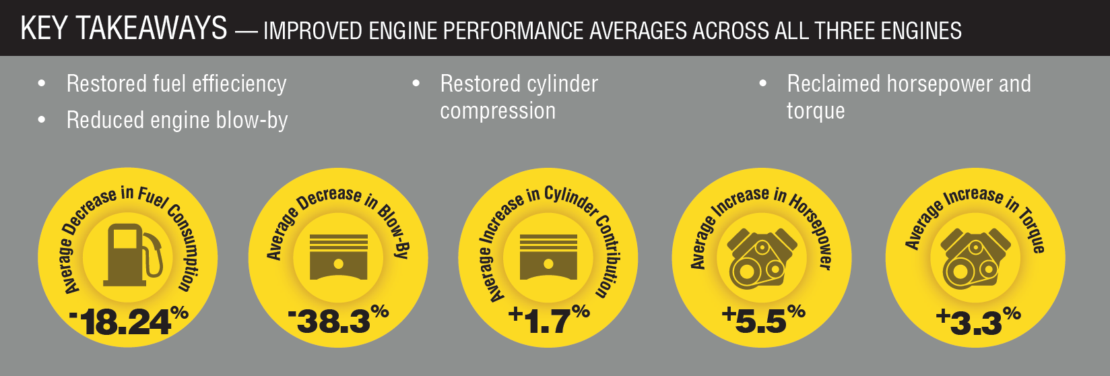

Prior to preventive maintenance, the weakest cylinder on average showed 5.2% less compression than the strongest cylinder in Engines 1 and 2. After the two services were performed to remove carbon deposits, all cylinders measured within 2.6% of each other, demonstrating restoration of piston ring function. Engine 3, with the lowest mileage, showed a 0.1% drop in cranking compression, indicating that it was in better pre-service condition than the two junkyard engines.

Blow-By

Engine blow-by was measured during each fuel run on the dynamometer. Engines 1 and 2 demonstrated an average reduction of 55.4% in blow-by levels following the service, while Engine 3 showed a 4.1% reduction. Even with 46,000 miles, Engine 3 was demonstrating wear in the combustion chamber sealing. These results indicate that blow-by increases as mileage increases, and reducing the amount of blow-by helps lessen engine oil oxidation and premature wear in downsized turbocharged engines.

Fuel Consumption

The fuel mass flow rate was measured at over a million data points per run, each of which ranged 8–10 hours at the same engine load, temperature, and ambient conditions. Engines 1 and 2 showed an average improved fuel efficiency of 21.3% post-treatment. Engine 3 showed an 11.2% improvement. These results are evidence of a marked increase in fuel efficiency for all three engines after receiving the services.

Horsepower and Torque

Post-service, Engine 1 showed a 7.9% increase in horsepower and a 4.1% rise in torque. Engine 2 attained 8.3% increase in horsepower and a 2.8% rise in torque. Engine 3 had a 0.4% increase in horsepower and a 3% rise in torque. Both horsepower and torque performance in the three engines increased after the preventive maintenance services were performed.

Final Thoughts

All three engines considered in this study initially exhibited performance loss due to buildup of deposits. After two BG preventive maintenance services, all three engines recovered more power output and better fuel efficiency, along with less blow-by. The results affirm that BG products and preventive maintenance services help keep today’s downsized turbocharged engines running strong and efficiently, ready for the road ahead.