Sludge be gone

Sludge buildup in Volkswagen/Audi engine

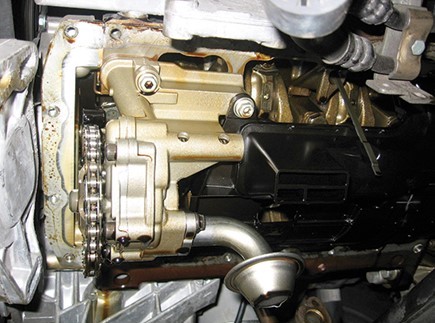

The same Volkswagen/Audi engine after BG Dynamic Engine Cleaner Service

Ta-DA!

It took almost two years, but in the end, BG and Volkswagen/Audi created the BG Dynamic Engine Cleaning Service utilizing BG Dynamic Engine Cleaner, Part No. 103, and a new service tool with special adaptors and filters.

“It’s harder than it looks,” Harold says. “In reality it’s complicated, that is… if you expect the car to survive the process.” Often, sludge is a mixture of moisture that has been trapped inside the engine with oxidized oil that should have been changed more frequently.

The goal was to return the car to the street for a normal life with the original owner, a fully restored vehicle that would likely not have any more sludge problems. “Of course a good maintenance program with BG EPR® Engine Performance Restoration®, PN 109, and BG Advanced Formula MOA,® PN 115, will help ensure a trouble-free future for these vehicles,” Harold says. “Volkswagen/Audi is working on a maintenance program and we hope it includes these BG products.”