Spiro Morogiannis | BG Training Manager and BGU Instructor

Effective time management improves shop efficiency, customer satisfaction, and profitability. Let’s discuss low-hanging fruit to create more time in your shops.

Time “opportunity” is a shop’s greatest revenue-producing tool that can be impacted by best practices. We can never get time back, and we never have enough. What if we could streamline everyday practices to free up more time? When time management opportunities are maximized, production and profitability skyrocket.

The Value of Time in an Auto Shop

Identifying the importance of time creation allows you to see areas of shop opportunity without making drastic operational changes. Shop owners all have a common goal: Get more customers. As great as this sounds, the greatest opportunities lie within existing time management practices and processes with your existing customer base.

If you get more customers but aren’t thorough and concise with the ones you have, why add more? To overlook more vehicles or deal with more chaos? Maximize your shop’s basic processes to create more time and labor opportunities.

The areas of instant time improvement are as follows: scheduling, MPI quarter time process, and tech downtime practices. Consider applying changes with one key point in mind: We never get time back. Maximize every time opportunity without sacrificing quality and improve it to reduce potential comebacks. Your customers will thank you and your good reputation will speak for itself.

Immediate Time Best Practices

In the fast-paced shop environment, distractions make it easy to glance at your shop’s numbers, not truly dissect them. A few metrics can show the true pulse of your shop’s time efficiency:

- Labor efficiency/tech efficiency. Take your tech’s total billed hours and divide by the hours physically worked. If your shop stays busy and your flat-rate technicians aren’t close to 100%, there’s a problem:

- You may be doing too much heavy line work with slow turnaround time.

- You have excessive downtime between jobs.

- Techs aren’t assigned to other vehicles when waiting on parts or approvals.

- Techs aren’t working a proper balance of high-labor efficiency maintenance jobs to large repair work.

- The repair work isn’t maximizing the shop’s time efficiency. Are you doing lengthy electrical diagnostics? Or fast-turnaround suspension, brake, and maintenance work? This matters when maximizing every tech’s labor efficiency numbers.

- Time management via MPI. Quarter-time inspections create more sold labor. Hold your techs (especially lube techs) to this process, and it will change the course of your shop’s time efficiency and upselling opportunities. Give the advisor time to talk with the customer about items found during the MPI. This sets the table for future work.

- Effective check-ins and drop-offs. Set customer expectations with check-in and drop-off times instead of appointments: “We will get you checked in. Once your vehicle is written up, our technician will perform a safety inspection and we’ll communicate the results, along with the vehicle concerns you came in for. We want you to know everything we see so you can make an informed decision.”

- 10:30 a.m. and 2:30 p.m. call-backs. Allow time for customers to make accommodations if they have to. Perform your morning customer call-backs at 10:30 to give them time to plan around lunch or for the rest of the day. Contact afternoon check-ins by 2:30 so they can plan to pick up their vehicle or get it a different day. These time management exercises allow cars to get in and out fast—with better customer communication.

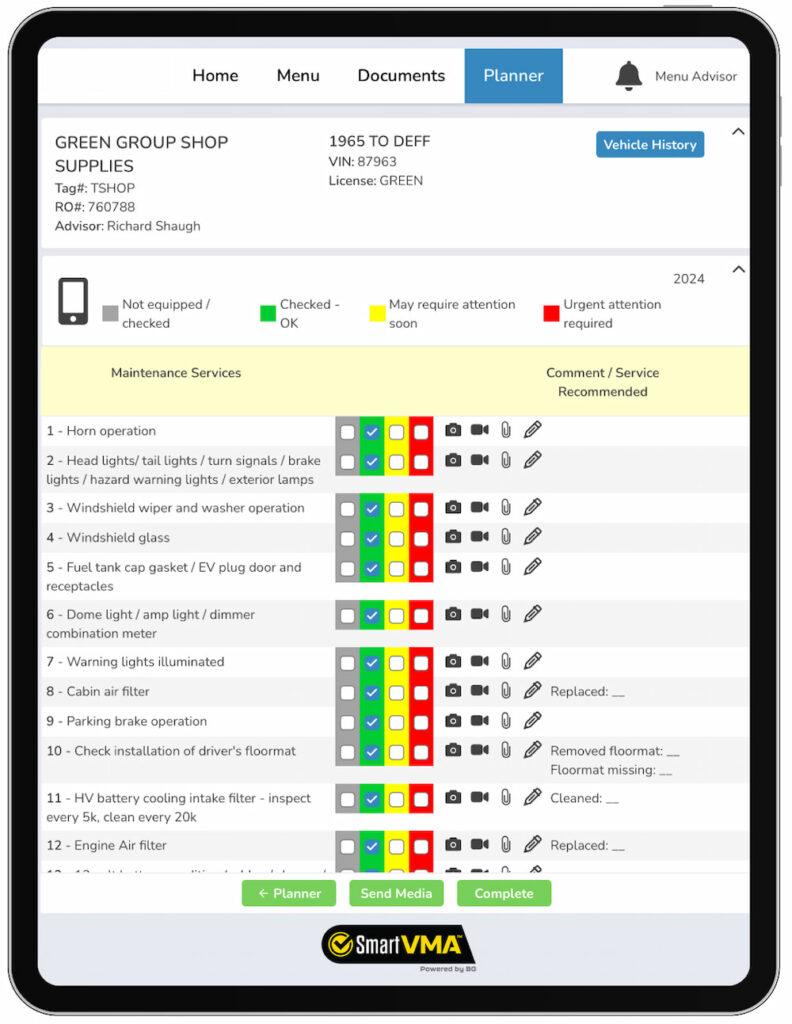

- Digital shop management programs. The right shop management system is the ULTIMATE time management gift. Companies offer different features, but digital inspections, estimates, and notifications save incredible amounts of time upfront and better orchestration of the back end, which all contribute to better shop time management.

Staying Organized

A clean, organized shop is more-efficient—fewer misplaced tools and parts, less chaos, and a much safer work environment. Designate time at the end of each day to allow techs to reset for the next day.

For hourly techs: Add to their job descriptions that they manage shop tooling, cleanliness, trash duties, sweeping, and general shop cleanup when bays are slow.

Effective communication processes must exist between technicians, service advisors, and customers. If you can keep techs on task while advisors stay on course, you’re maximizing time.

Even these small-time management steps create opportunities that will drive business. Smart scheduling, proper communication, accountability of processes, and shop management exercises create time we have otherwise lost.

Time management is a continual shop effort. Regularly assess and refine these strategies into long-term benefits in shop efficiency, customer satisfaction, and increased shop revenue. Challenge yourself to implement (or fine-tune) these small strategies, and let the results speak for themselves.

About the Author

Spiro Morogiannis has more than 15 years in the automotive industry, with 8+ years at BG Products. With a deep understanding of maintenance and repair operations, as well as specializing in independent automotive shops, Spiro brings valuable insights into best practices and industry trends.